- Home

- PAC

Refrigeration and HVAC Specialist

PAC

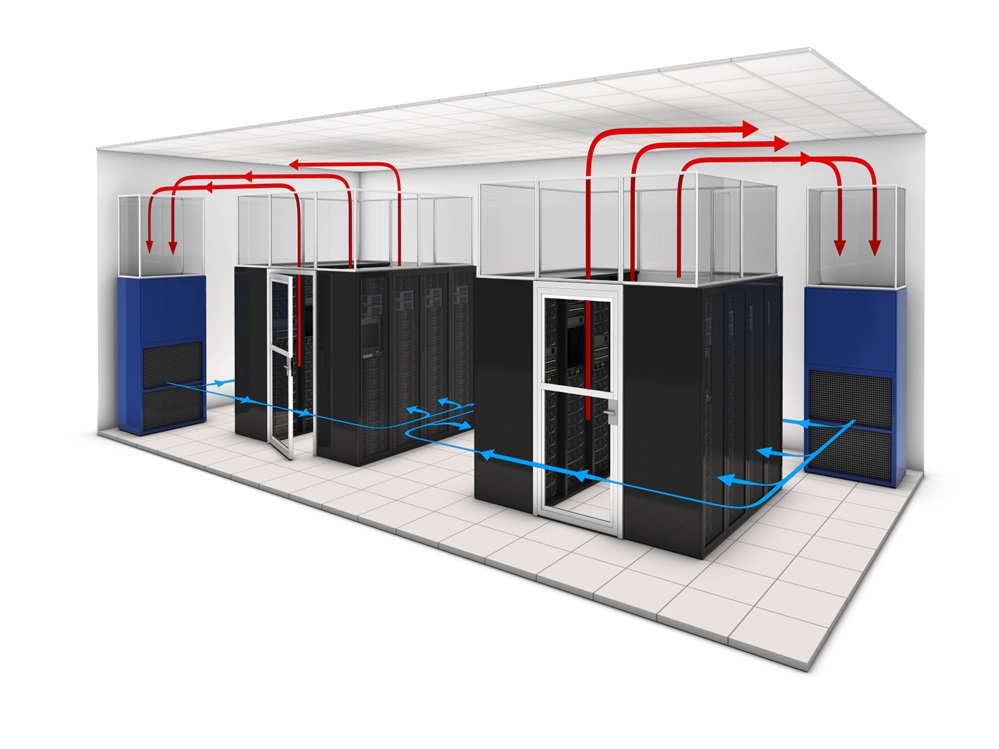

PAC is a high-performance cooling system designed for environments that require strict temperature and humidity control, such as data centers, server rooms, laboratories, and medical facilities. Unlike standard comfort air conditioners, which focus on human comfort, precision AC units maintain stable environmental conditions to protect sensitive equipment from overheating and humidity fluctuations.

These systems help prevent downtime, overheating, and equipment failure, making them essential in mission-critical environments.

Key Features:

High Accuracy: Maintains temperature within ±1°C and humidity within ±5%.

Continuous Operation: Designed for 24/7 operation without failure.

Efficient Airflow Management: Uses higher air exchange rates and advanced filtration.

Humidity Control: Manages moisture levels to prevent static electricity and condensation.

Energy Efficiency: Uses variable-speed fans and advanced cooling technologies to optimize power consumption.

The difference between precision AC and normal AC

- Purpose & Application:

Precision AC: Designed for critical environments like data centers, server rooms, laboratories, and hospitals, where precise temperature and humidity control is essential.

Normal AC: Designed for comfort cooling in homes, offices, and commercial spaces, focusing on human comfort rather than strict environmental control. - Temperature & Humidity Control:

Precision AC: Maintains tight control over temperature (±1°C) and humidity (±5%).

Normal AC: Less precise; temperature fluctuates more, and humidity control is minimal. - Cooling Efficiency & Duty Cycle:

Precision AC: Works continuously (24/7) with high efficiency to manage heat loads from servers and equipment.

Normal AC: Designed for intermittent use with longer rest cycles, making them unsuitable for non-stop operation. - Airflow & Filtration:

Precision AC: Higher airflow rate with advanced filtration to remove dust and contaminants.

Normal AC: Lower airflow and basic filtration, sufficient for human comfort but not ideal for sensitive equipment. - Heat Load Handling:

Precision AC: Manages high heat loads generated by electronic equipment.

Normal AC: Optimized for cooling human-occupied spaces, not heavy heat-generating devices. - Longevity & Maintenance:

Precision AC: Built for durability with heavy-duty components, requiring regular maintenance but having a longer lifespan.

Normal AC: Shorter lifespan if used for critical applications, with simpler maintenance needs.

PAC Selection Tips

- Accuracy Requirements:

The primary function of a precision air conditioner is to maintain stable temperature and humidity levels. When selecting a unit, it is essential to choose one with high-precision temperature and humidity control based on actual needs.

For example, data centers and laboratories require minimal temperature fluctuations, typically within ±0.5℃ or even more precise.Lorem ipsum irure ad minim laboris in nostrud consequat ad excepteur eu non est. - Proper Cooling Capacity Calculation

Choosing the appropriate cooling capacity helps prevent overloading or inefficiency. When calculating the required cooling capacity, consider the following factors:

Room/Equipment Room Size

Equipment Power and Heat Generation

Number of Personnel and Heat Load

Other Heat Sources (e.g., UPS power supplies)

It is recommended to refer to manufacturer-provided cooling capacity formulas or consult a professional engineer. - Selection of Additional Functions:

Modern precision air conditioners integrate various features, including: Air Purification (suitable for environments requiring high cleanliness)

Humidification/Dehumidification (maintaining humidity between 40%-60% to prevent static electricity or equipment corrosion)

Remote Monitoring (real-time monitoring and control of temperature and humidity, ideal for unattended equipment rooms)

Select only the necessary features according to the specific application to avoid unnecessary cost increases. - Energy Efficiency Consideration: (EER)

A high energy efficiency ratio (EER) means lower energy consumption and operating costs. It is advisable to choose:

Air conditioners with inverter technology to enhance part-load efficiency

Models with energy-saving modes that adjust operation based on load conditions

Products that meet national or international energy efficiency standards - Brand and After-Sales Service:

Precision air conditioners are high-value equipment used for long-term operation, making reliable after-sales service crucial:

Choose reputable brands with a strong market presence

Check the brand’s service network and maintenance response time

Ensure the manufacturer provides quick repair services and long-term spare parts supply